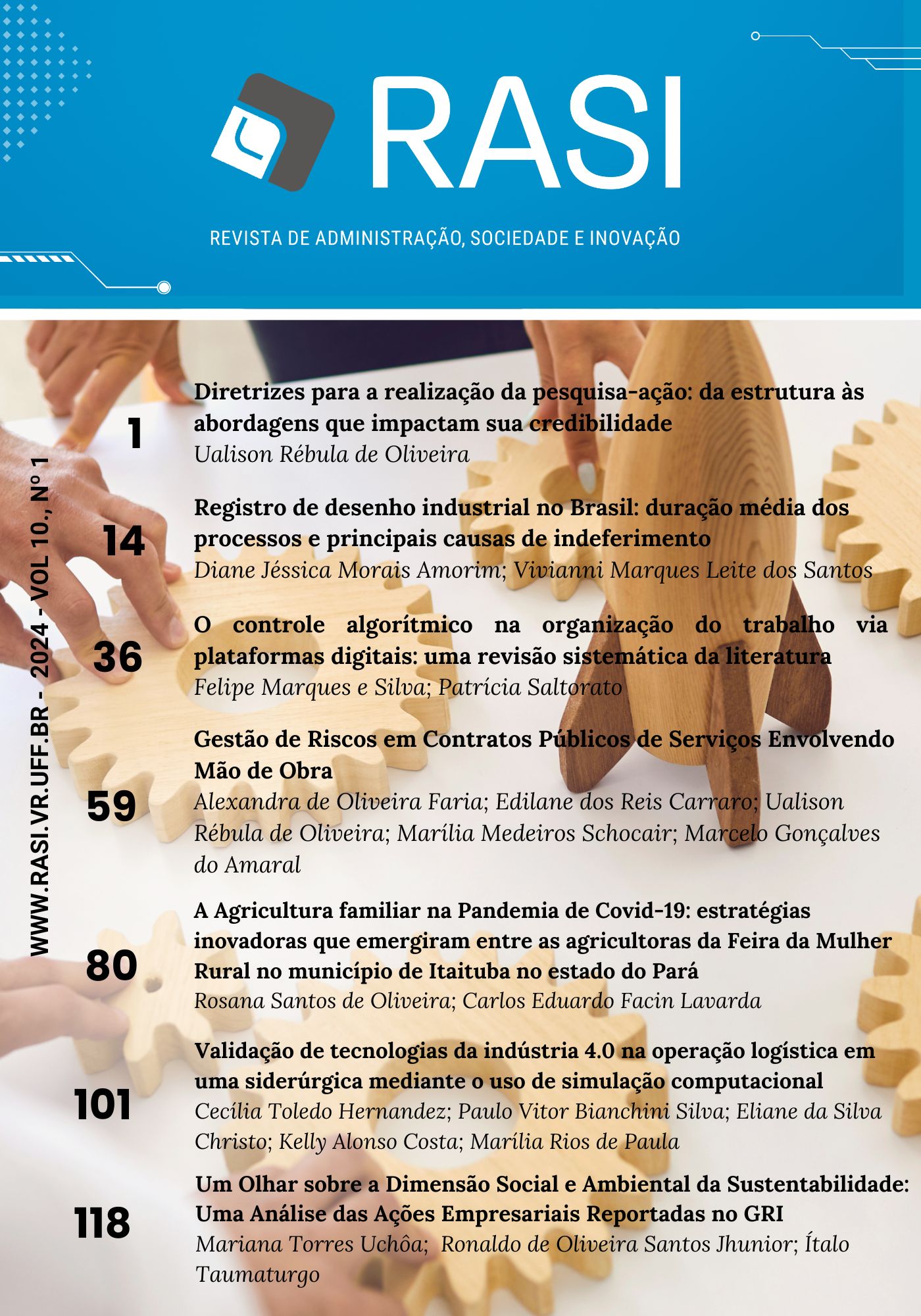

Português Validation of industry 4.0 technologies in logistics operations at a steel plant through computational simulation

DOI:

https://doi.org/10.20401/rasi.10.1.882Keywords:

PortuguêsAbstract

The steel production generates residues, one of which is blast furnace slag, primarily used in cement manufacturing. The movement of blast furnace slag involves a complex road logistics system, using trucks or dump trailers. Industry 4.0 has enabled various solutions across different sectors, including logistics, allowing for operational and economic gains. This article aims to showcase the benefits achieved through evaluating Industry 4.0 solutions in the operation and transportation of blast furnace slag within a steel plant. Computational simulation was employed to establish scenarios and test different models. Data collection was conducted through questionnaires, observations, and document analyses. Four different scenarios were tested, alternating between current production and maximum production, with or without the use of Industry 4.0 solution tools, to optimize resource allocation. As a result, three Industry 4.0 technology solutions were identified, one of which was tested with two of its tools across four different scenarios. These simulated scenarios demonstrated economic gains ranging from 15 to 30% when adopting Industry 4.0 solutions. These gains also manifest in increased resource availability and reduced cycle time for operations. The developed and validated computational simulation model can be replicated in other situations and adapted for other logistics cases, considering relevant changes and their underlying assumptions.

Downloads

References

Andrade, M. M. (2017). Introdução à Metodologia do Trabalho Científico. 10. ed. São Paulo: Atlas

Andrade, C., & Gonçalo, C. (2022). Plataformas E Ecossistemas: Revista De Administração, Sociedade E Inovação, 8(2), 96–118. Https://Doi.Org/10.20401/Rasi.8.2.573

Ballou, Ronald. H. (2009). Gerenciamento Da Cadeia De Suprimentos: Logística Empresarial. (Bookman, Ed.; 5th Ed.).

Barreto, L., Amaral, A., & Pereira, T. (2017). Industry 4.0 Implications In Logistics: An Overview. Procedia Manufacturing, V. 13, 1245–1252.

Corrêa, J. S., Sampaio, M., & Barros, R. De C. (2020). An Exploratory Study On Emerging Technologies Applied To Logistics 4.0. Gestão & Produção, 27(3). Https://Doi.Org/10.1590/0104-530x5468-20

Costa, R. A. (2019). Soluções Da Indústria 4.0 Para Melhoria Da Eficiência Logística De Processos Logísticos. Dissertação De Mestrado (Mestrado Em Engenharia De Produção). Universidade Federal Fluminense.

Creswell, J. W., & Creswell, J. D. (2021). Projeto de Pesquisa: Métodos qualitativo, quantitativo e misto. 5. ed. Porto Alegre: Penso, E-book.

C.S.C.M.P. (2013). Council Of Supply Chain Management Professionals. Supply Chain Management Terms And Glossary.

Dantas, M. (2003). Informação E Trabalho No Capitalismo Contemporâneo. Lua Nova: Revista De Cultura E Política, 5–44.

Drees, J. (2016). Logistics 4.0: Tailored Solutions For The Future. In International Press Workshop. Gopali & Co.

Ferreira, S. C., & De Paula, G. M. (2021). Primeiros Impactos Da Indústria 4.0 Sobre O Setor De Papel E Celulose. Revista De Administração, Sociedade E Inovação, 7(1), 124–139. Https://Doi.Org/10.20401/Rasi.7.1.522

Franco, G. N. (2016). Estudo Para Redução De Permanência De Veículos Apoiado Pela Simulação Em Computador. In 35th Logistic Seminar (Pp. 35–42).

Freitas Filho, P. J. (2008). Introdução à modelagem e simulação de sistemas: com aplicações em arena. 2. ed. Florianópolis, Visual Books Ltda.

Gil, A. C. (2022). Como Elaborar Projetos De Pesquisa (7th Ed.).

Goldsman, D. (2007). Introduction To Simulation. 2007 Winter Simulation Conference, 26–37.

Golovianko, M. (2023). Industry 4.0 Vs. Industry 5.0: Co-Existence, Transition, Or A Hybrid. Procedia Computer Science, V. 217, 102–113.

Gunal, M. M., & Karatas, M. (2019). Industry 4.0, Digitisation In Manufacturing, And Simulation: A Review Of The Literature. Simulation For Industry, 4(0), 19–37.

Kagermann, H., Wahlster, W., & Helbig, J. (2013). Securing The Future Of German Manufacturing Industry: Recommendations For Implementing The Strategic Initiative Industrie 4.0. Final Report Of The Industrie 4.0 Working Group. Acatech - National Academy Of Science And Engineering.

Kolberg, D., & Zühlke, D. (2015). Lean Automation Enabled By Industry 4.0 Technologies. Ifac-Papersonline, V. 48, 1870–1875.

Lima, E. C., & Neto, C. (2017). Revolução Industrial: Considerações Sobre O Pioneirismo Industrial Inglês. Revista Espaço Acadêmico, V. 1, N. 194, 102–113.

Abreu, C. E., Rodrigues Barbosa Gonzaga, D., Dos Santos, F. J., Ferreira De Oliveira, J., De Morais Oliveira, K. D., Morais Figueiredo, L., Nascimento, M. P., Gomes De Oliveira, P., De Souza Yoshinaga, S. T., Taveira De Oliveira, T., Silva Da Mata, V., & Dos Santos Gonçalvesa, G. A. (2018). Indústria 4.0: Como As Empresas Estão Utilizando A Simulação Para Se Preparar Para O Futuro. Revista De Ciências Exatas E Tecnologia, 12(12), 49. Https://Doi.Org/10.17921/1890-1793.2017v12n12p49-53

Motta, M. J., & Lusvargui, G. C. (2018). Logística 4.0 Desafios E Oportunidades Na Gestão Da Cadeia De Suprimentos Moderno.

Nahavandi, S. (2019). Industry 5.0—A human-centric solution. Sustainability, v. 11, n. 16, 4371.

Nambisan, S., Zahra, S. A., & Luo, Y. (2019). Global platforms and ecosystems: Implications for international business theories. Journal of International Business Studies,50(9.

Noronha, G. D. (2020). Estudo de um Modelo Logístico Viável para Implantação de uma Linha de Bandagem através da Simulação. Anais do Simpósio Brasileiro De Pesquisa Operacional, João Pessoa.

Oztemel, E., & Gursev, S. (2020). Literature review of Industry 4.0 and related technologies. Journal of Intelligent Manufacturing, v. 31, 127–182.

Rocha, A. M., Silva, P. V. B., Andrade, J. C. E. de, & Franco, G. N. (2013). Modelo computacional da movimentação ferroviária na usina Presidente Vargas (pp. 48–59). 32o Seminário de Logística.

Sacomano, J. B. (2018). Indústria 4.0 (1.).

Santos, B. P. (2018). Indústria 4.0: desafios e oportunidades. Revista Produção e Desenvolvimento, v. 4, n. 1, 111–124.

Saw, H. S. (2021). Sustainability and Development of Industry 5.0.

Soares, V. R. (2022). Elaboração de um plano de manutenção em uma empresa do setor de sacarias de cimento de Santa Catarina com base nas metodologias de manutenção preventiva. In Monografia (Engenharia de Produção). Instituto Federal de Santa Catarina.

Tessarini, G., & Saltorato, P. (2018). Impactos da indústria 4.0 na organização do trabalho: uma revisão sistemática da literatura. Revista Produção Online, 18(2), 743–769. https://doi.org/10.14488/1676-1901.v18i2.2967

Wang, K. (2016). Logistics 4.0 solution: new challenges and opportunities. Proceedings of the 6th International Workshop of Advanced Manufacturing and Automation.

Yamanda, V. Y., & Martins, L. M. (2019). Indústria 4.0: um comparativo da indústria brasileira perante o mundo. Revista Terra & Cultura: Cadernos de Ensino e Pesquisa, 34.

Yin, R. K. (2015). Estudo de Caso: Planejamento e Métodos – 5. ed. São Paulo: Bookman, E-book.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 Review of Administration, Society and Innovation

This work is licensed under a Creative Commons Attribution 4.0 International License.

RASI, in accordance with Law No. 9,610 of February 19, 1998, which amends, updates and consolidates Brazilian copyright law and makes other provisions, adopts the following conditions of the Copyright Assignment:

1. RASI maintains, with the transfer of copyrights, the possession of rights over the content published;

2. The author retains his moral rights of the content, including the right to be identified as the author whenever the content is published;

3. Despite the attribution of copyright, the author retains the right to reuse the material in future collections of his own work without encumbrance. The acknowledgments of the previous publication in the RASI are the only requirements in such cases;

4. The author may make photocopies of the content, or distribute it by electronic mail or fax, provided that they are intended for their own classes and for the purpose of meeting research objectives, provided that: (a) such copies are not resold and (b) reference to the original source of the publication and the name of the RASI are clearly indicated on all copies made of the document.